Technology

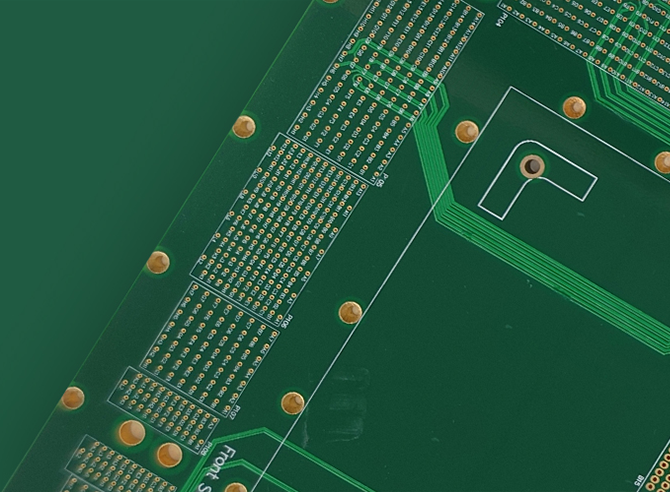

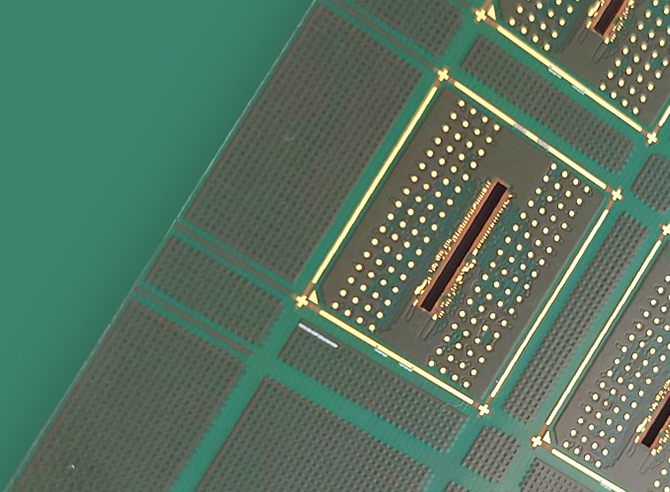

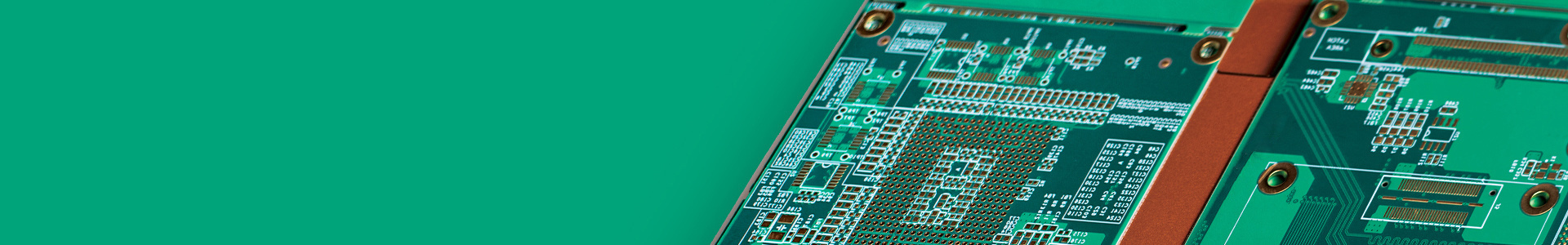

Flexible & Rigid Flexible PCBs

Your reliable PCB solutions provider

The flexible and rigid-flex products provide a reliable solution for the integration of multiple rigid circuit board assemblies into a single board. These products can also reduce the weight and space requirements of the board.

A rigid-flex printed circuit board is a type of electronic device that combines the advantages of both flexible and rigid circuits. This type of board can be used to achieve various features, such as signal transmission and stability. JOVEPCB Enterprise Ltd. is a leading producer of this kind of board, and it offers a wide range of products and expertise.

JOVEPCB Enterprise Ltd.' s engineers are able to provide our customers with design guidance and help them find the optimal solutions for their specific requirements. Through our extensive experience in the field of rigid-flex and flex- dependent designs, we are able to help them improve their overall yield and reduce their cost of production. This close collaboration with our customers enables them to create innovative and sustainable solutions that help our customers to optimize the design of their products.

What can we do?

In response to the increasing demand for flexible printed circuit boards, JOVEPCB Enterprise Ltd. is also able to support volume production of the core HDI technology in combination with Flex printed circuit boards.

Technical Characteristics

|

|

Manufacturing Process

Technical Parameter

Technical Parameters for Rigid-Flex PCB

| No. | Capabilities | Standard Production | Advanced Production | ||

|---|---|---|---|---|---|

| 1 | Panel size | Double side | ENIG/Immersion Tin | 250/500*900mm | 250/500*1200mm |

| ≥4 layers | ENIG/Immersion Tin | 250/500*710mm | 250/500*1200mm | ||

| 2 | Stack up | Blind/Buried board | Pressing times | MAX≤3times | MAX≤3times |

| Copper thickness | Inner layer | 1/3OZ-2OZ(FCCL) MAX 2OZ |

1/3OZ-2OZ(FCCL) MAX 2OZ |

||

| Outer layer | 1/3OZ-3OZmm | 1/3OZ-3OZmm | |||

| Min Dielectric ThK | 0.025mm(FCCL) 0.043mm(CCL) |

0.0125mm(FCCL) 0.043mm(CCL) |

|||

| Max Layer count | 18L | 24L | |||

| Final board ThK Tolerance | ThK≤1.0mm | ±0.1mm | ±0.1mm | ||

| ThK>1.0mm | ±10% | ±10% | |||

| 3 | Line/Space | Inner Layer | 1/3OZ | 2/2mil | 1.5/1.5mil |

| 1/2OZ | 2.5/2.5mil | 2/2mil | |||

| 1OZ | 3.0/3.0mil | 3.0/3.0mil | |||

| 2OZ | 6/5.5mil | 6/5.5mil | |||

| Outer layer | 1/3OZ | 3/3mil | 3/3mil | ||

| 1/2OZ | 3.5/3.5mil | 3.5/3.5mil | |||

| 1OZ | 5/5mil | 5/5mil | |||

| 2OZ | 6/8mil | 6/8mil | |||

| 3OZ | 8/11mil | 8/11mil | |||

| Pad Tolerance | ≤12mil | ±1.2mil | ±1.2mil | ||

| >12mil | ±10% | ±10% | |||

| 4 | Drill | Mechanical Drill size | 0.15-6.35mm | 0.1-6.35mm | |

| PTH Hole Tolerance | ±0.075mm | ±0.075mm | |||

| NPTH Hole Tolerance | ±0.05mm | ±0.05mm | |||

| Plated slot tolderance | Long slot | ±0.075mm | ±0.075mm | ||

| Short Slot | ±0.1mm | ±0.1mm | |||

| Aspect Ratio | DHS=0.15mm | 7:1 | 7:1 | ||

| DHS=0.2mm | 10:1 | 10:1 | |||

| DHS ≥0.25mm | 15:1 | 15:1 | |||

| Back drill(Back drill/Depth-control drill) | Hole size | 0.4-6.35mm | 0.4-6.35mm | ||

| Back drill relative to through hole | ≥0.2mm | ≥0.2mm | |||

| Back drill depth tolerance | ±0.1mm | ±0.1mm | |||

| Stub length | 0.05-0.25 | 0.05-0.25 | |||

| 5 | Min BGA | 1.0mm BGA 2 trace | Yes | Yes | |

| 0.8mm BGA 1 trace | Yes | Yes | |||

| 0.65mm BGA | Yes | Yes | |||

| 0.5mm BGA | Yes | Yes | |||

| 0.4mm BGA | Yes(Sample) | Yes(Sample) | |||

| 6 | Laser | Laser hole size | 0.07-0.2mm | 0.05-0.2mm | |

| Laser hole size | ≤1:1 | ≤1:1 | |||

| 7 | Soldermask | Color | Green,Yellow,Black,Blue,Red, White, Matt green | Green,Yellow,Black,Blue,Red, White, Matt green | |

| SM ThK | Single print thickness | 10-30um | 10-30um | ||

| Double print thickness | 20-60um | 20-60um | |||

| The line corner | ≥5um | ≥5um | |||

| Min SM dam | normal color 3.0mil,other color min 4mil | normal color 3.0mil,other color min 4mil | |||

| 8 | Resin plugging | hole size | 0.15-0.6mm | 0.1-0.6mm | |

| PCB ThK | 0.3-3.0mm | 0.3-3.0mm | |||

| Resin plugging aspect ratio | 12:1 | 12:1 | |||

| 9 | Impedance | Capability of Impedance | Single line impedance<50Ω | ±5Ω | ±3.5Ω |

| Single line impedance≥50Ω | ±10% | ±7% | |||

| Differential line impedance | ±10% | ±7% | |||

Technical Parameters for Flex PCB

| No. | Capabilities | Standard Production | Advanced Production | ||

|---|---|---|---|---|---|

| 1 | Panel size | Double sided | ENIG/Immersion Tin | 250/500 *900mm | 250/500 *1200mm |

| ≥4 layers | ENIG/Immersion Tin | 250*800mm | 250*800mm | ||

| 2 | Stack up | Blind/Buried board | Lamination times | MAX≤2times | MAX≤2times |

| Copper thickness | Inner layer | 1/3OZ-2oz MAX 2OZ |

1/3OZ-2oz MAX 2OZ |

||

| Outer layer | 1/3OZ-2OZ | 1/3OZ-3OZ | |||

| Min Dielectric ThK | 0.0125mm | 0.0125mm | |||

| Max Layer count | 6L | 8L | |||

| 3 | Line/Space | Inner Layer | 1/3OZ | 2/2mil | 1.5/1.5mil |

| 1/2OZ | 2.5/2.5mil | 2/2mil | |||

| 1OZ | 3.0/3.0mil | 3.0/3.0mil | |||

| 2OZ | 6/5.5mil | 6/5.5mil | |||

| Outer Layer | 1/3OZ | 3/3mil | 3/3mil | ||

| 1/2OZ | 3.5/3.5mil | 3.5/3.5mil | |||

| 1OZ | 5/5mil | 5/5mil | |||

| 2OZ | 6/8mil | 6/8mil | |||

| 3OZ | 8/11mil | 8/11mil | |||

| Pad Tolerance | ≤12mil | ±1.2mil | ±1.2mil | ||

| >12mil | ±10% | ±10% | |||

| 4 | Drill | Mechanical Drill size | 0.15-6.0mm | 0.1-6.5mm | |

| PTH Hole Tolerance | ±0.075mm | ±0.075mm | |||

| NPTH Hole Tolerance | ±0.05mm | ±0.05mm | |||

| Plated slot tolerance | Long slot | ±0.075mm | ±0.075mm | ||

| Short Slot | ±0.1mm | ±0.1mm | |||

| 5 | Min BGA | 1.0mm BGA 2 trace | Yes | Yes | |

| 0.8mm BGA 1 trace | Yes | Yes | |||

| 0.65mm BGA | Yes | Yes | |||

| 0.5mm BGA | Yes | Yes | |||

| 0.4mm BGA | Yes(Sample) | Yes(Sample) | |||

| 6 | Laser | Laser hole size | 0.07-0.2mm | 0.05-0.2mm | |

| Laser hole size | ≤1:1 | ≤1:1 | |||

| 7 | Soldermask | Color | Green,Yellow,Black,Blue,Red, White, Matt green | Green,Yellow,Black,Blue,Red, White, Matt green | |

| SM ThK | Single print thickness | 10-30um | 10-30um | ||

| Min SM dam | normal color 3.0mil,other color min 4mil | normal color 3.0mil,other color min 4mil | |||

| 8 | Impedance | Capability of Impedance | Single line impedance<50Ω | ±5Ω | ±3.5Ω |

| Single line impedance≥50Ω | ±10% | ±7% | |||

| Differential line impedance | ±10% | ±7% | |||

| 9 | Lamination | Coverlay alignment tolerance | ±0.15mm | ±0.1mm | |

| 10 | Adhere stiffener | Stiffener alignment tolerance | ±0.2mm | ±0.15mm | |

| 11 | Outline | Laser/Punch | ±0.05mm | ±0.05mm | |

| 12 | Construction | Air Gap availability | Yes | Yes | |

Products & Technologies

Contact Us and Support

Keep an eye on us and keep abreast of the latest product

information and trends.

Technology

Copyright © Copyright @ JOVEPCB Enterprise Ltd. | Guangdong ICP Filing No. 18041806