Technology

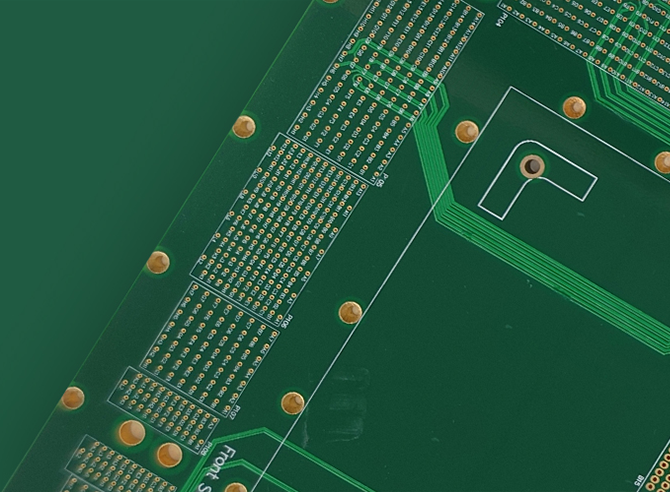

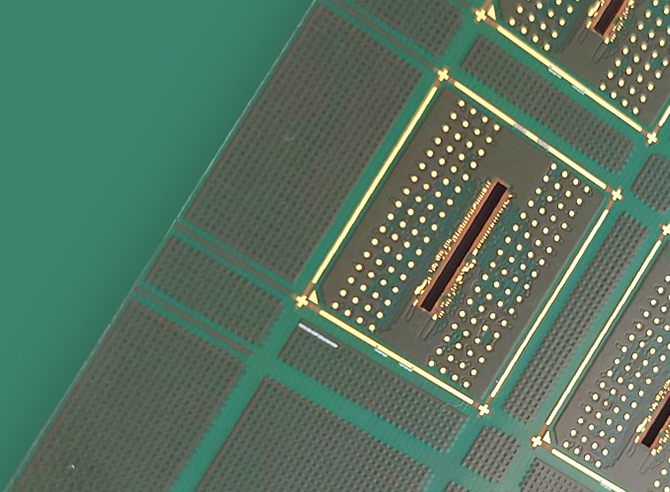

Insulated Metallic Substrate PCBs

Your reliable PCB solutions provider

A metal-based PCB, also known as a IMSPCB, is composed of a metal substrate, which is usually either copper or aluminum. Due to its superior thermal dissipation, it is commonly used in various applications such as power supplies and LED lights.

JOVEPCB Enterprise Ltd. has extensive experience of producing IMS printed circuit boards, which are commonly used for powering electronic components such as power meters and LED lights. These are also known as heat sinks. The base material used for these PCBs is either copper or aluminum.

What can we do?

For over ten years, JOVEPCB Enterprise Ltd. has been continuously working on the production of metal substrates. It is capable of producing both aluminum and copper substrates, which have a combined thermal conductivity of up to 100 percent.

Technical Characteristics

|

|

Manufacturing Process

Technical Parameter

| No. | Capabilities | Standard Production | Advanced Production | |

|---|---|---|---|---|

| 1 | Number of Layer | 2 Layer | 4 Layers | |

| 2 | Base Material | Aluminum Based | Aluminum Based | |

| 3 | Metal Substrate Thickness | 0.80 mm -2.0 mm | 0.50 mm -3.20 mm | |

| 4 | Dielectric layer Thickness | 75um、100um、125um | 50um、75um、100um、125um、150um | |

| 5 | Copper Thickness | Min. H OZ, Max. 4 OZ | Min. H OZ, Max. 6 OZ | |

| 6 | Thermal conductivity | 0.8-2.5w/m·k | 2.0-3.0w/m·k | |

| 7 | Electric strength | 30KV/mm | 40KV/mm | |

| 8 | Min. Line Width & Line Space | 0.10 mm | 0.08mm | |

| 9 | Min. Hole Diameter | Drilling /PTH | 0.8 mm | 0.60mm |

| Punching | 1.2 mm | 1.0 mm | ||

| 10 | Dimension Tolerance | Hole Position | ±0.08mm | ±0.05mm |

| Conductor Width(W) | ±20% Deviation of Master A/W | ±15% Deviation of Master A/W | ||

| Hole Diameter(H) | NPTH: ±0.05 mm | NPTH: ±0.03 mm | ||

| PTH: ±0.075 mm | PTH: ±0.05 mm | |||

| Outline Dimension | ±0.13 mm | ±0.10 mm | ||

| Conductors & Outline ( C - O ) | ±0.15 mm | ±0.13 mm | ||

| Warp and Twist | 0.75% | 0.50% | ||

| 10 | V-Cutting | Panel Size | 457.2mm X 610mm ( max. ) | 457.2mm X 610 mm ( max. ) |

| Board Thickness | 0.90 mm min. | 0.60 mm min. | ||

| Remain Thickness | 1/3 board thickness | 1/3 board thickness | ||

| Tolerance | ±0.13 mm | ±0.1 mm | ||

| Groove Width | 0.50 mm max. | 0.38 mm max. | ||

| Groove to Groove | 20 mm min. | 10 mm min. | ||

| Groove to Trace | 0.45 mm min. | 0.38 mm min. | ||

| 11 | Min Spacing from hole edge to hole edge | 0.50-1.60 (Hole Diameter) | 0.15mm | 0.10mm |

| 1.61-6.50 (Hole Diameter) | 0.15mm | 0.13mm | ||

| 12 | Minimum spacing between hole edge to circuitry pattern | PTH hole: 0.20mm | PTH hole: 0.13mm | |

| NPTH hole: 0.18mm | NPTH hole: 0.10mm | |||

| 13 | Image transfer Registration tolerance | ±0.10mm | ±0.08mm | |

| 14 | Test voltage | 5000V Max. | 10000V max. | |

Products & Technologies

Contact Us and Support

Keep an eye on us and keep abreast of the latest product

information and trends.

Technology

Copyright © Copyright @ JOVEPCB Enterprise Ltd. | Guangdong ICP Filing No. 18041806